3D Modelling and Assembly

2D Design

There are various softwares used for the ideation of the product. Some of the softwares used were Photoshop for raster images and Illustrator for vector designs. Listed below is a design for a modified HP printer from line art to area grouping to digital painting.

Modelling Process - Base

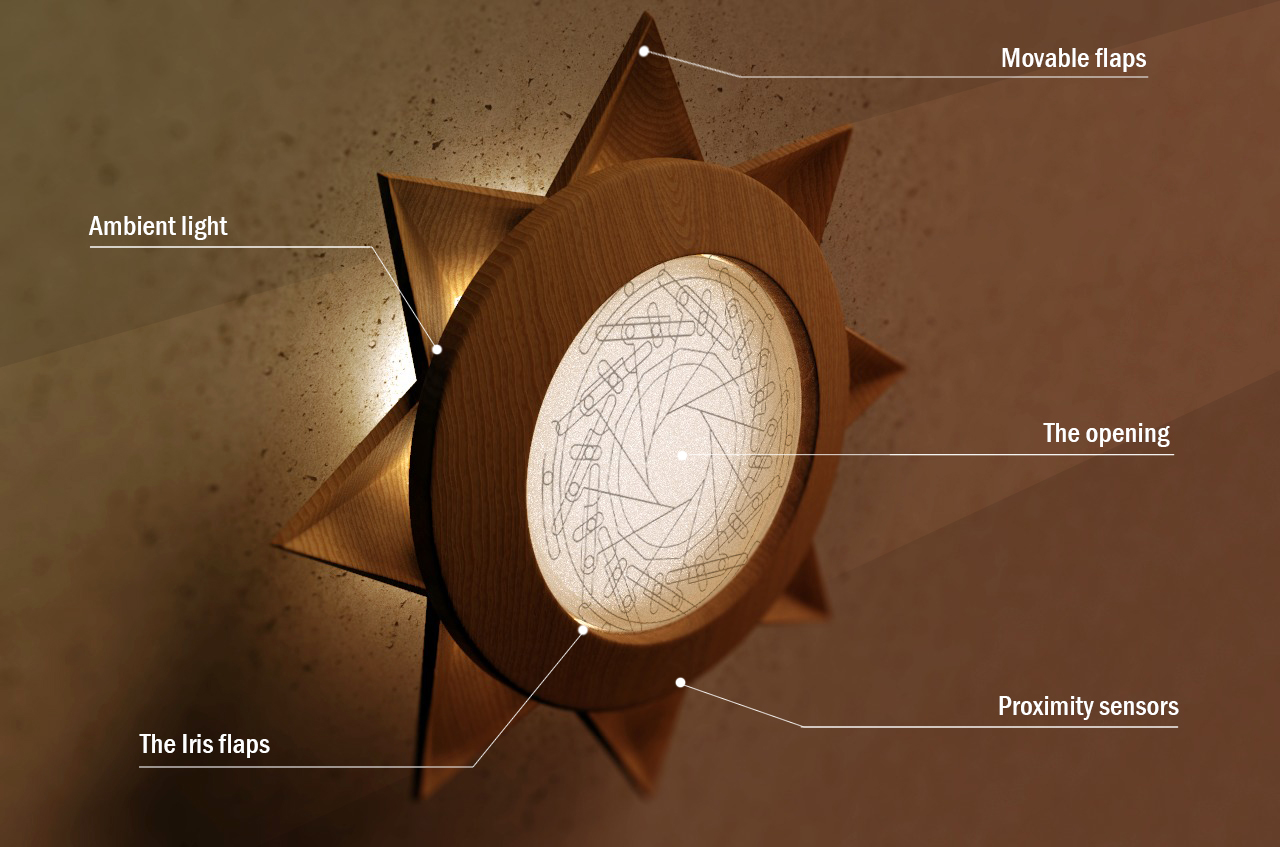

The first step in creating the product is sketching out the various ideas and variations of the final design. After having an idea of its overall appearance a concept model was made using Cinema 4D to better understand how the appearance looks in the desired settings. To visualize the lighting system Keyshot 7 was used and the output is shown below.

Using Solidworks to model the parts

Taking the project concept (ICARUS LAMP) as the subject to create, there are multiple parts to the product and hence all the part modelling is done directly in assembly mode.

The first part is inserted by selecting- "Insert a new part". Inside which the base is modelled. A new sketch is created on one of the primary planes. Two concentric circles are made with parametric dimensions - di and do. After fully constraining the sketch, it is extruded.

The next thing essential to the base are the slots to insert the shaft of each flap. Based on the stepper pulley used for the model, the inner diameter of 8mm is considered at a parametric distance from the center based on the inner and outer diameters of the base model.

The slot sketch is then cut using the 'Extrude Cut' feature. To create multiple slots around the base model, the circular pattern feature is used to duplicate the 'Extrude Cut' feature around the axis of the base.

And finally the base is extended as required based on the size of the flap that is to be developed. The extension is needed to hide the flaps when it is in the open position.

Modelling Process - Flaps

Since all the flaps work together to open and close the aperture completely, it is crucial to design the flaps so that it doesnt interact with eachother in any undesired way and it should not have any gaps between it while the mechanism takes place. To understand this better, an individual flap is first modelled in approximation. And this one flap is then duplicated alone the axiz of the base. When creating circular copies, the changes in position and orientation made in any one of the flap will translate to all the other flaps as shown below.